Conprofe Forming Taps: Boosting Efficiency in Electronics Manufacturing

December 1, 2025 10:32 am

December 1, 2025 10:32 amIn the high-stakes world of consumer electronics manufacturing, where microscopic tolerances and structural integrity are paramount, traditional thread-cutting methods often fall short. At Conprofe, we are redefining precision with our advanced Micro-Diameter Forming Taps. They reshape the metal grain structure through precise pressure, creating stronger, smoother threads without producing any chips. This results in threads with higher strength and superior surface finish, eliminating the critical risk of chip jamming in blind holes—a common challenge in delicate smartphone frames and other compact devices.

The Principle: Forging Threads, Not Cutting Them

The core principle behind forming taps is plastic deformation, a fundamentally different approach from traditional cutting. These taps feature a unique polygonal cross-section (such as triangular or square) with no flutes or cutting edges. As the tap is rotated into a precisely sized pre-drilled hole, its lobes apply immense pressure to the hole’s wall. This pressure forces the ductile metal to flow plastically and conform to the tap’s profile, essentially “kneading” the material into the precise shape of the thread. Consequently, this method requires the workpiece material to possess excellent plasticity and ductility, making it ideally suited for tough yet malleable materials like stainless steel, aluminum alloys, copper, and zinc alloys. This inherent advantage makes them ideal for the consumer electronics industry, eliminating chip disposal issues in delicate components and producing higher-strength threads perfect for repeated assembly and disassembly.

Engineered for Quality, Longevity, and Consistency

Our Conprofe Micro-Diameter Forming Taps are engineered for excellence:

Unmatched Surface Finish: A unique polishing process ensures a super-smooth surface with a quality of Sa 0.1µm or less, which virtually eliminates micro-defects and ensures consistent, high-integrity thread formation.

Low-Friction DLC Coating: The Diamond-Like Carbon (DLC) coating significantly reduces the coefficient of friction and provides low adhesion, preventing material pickup and galling.

Premium Material & Stability: Manufactured from selected high-end tungsten steel, our taps offer exceptional strength, extended tool life, and unwavering consistency.

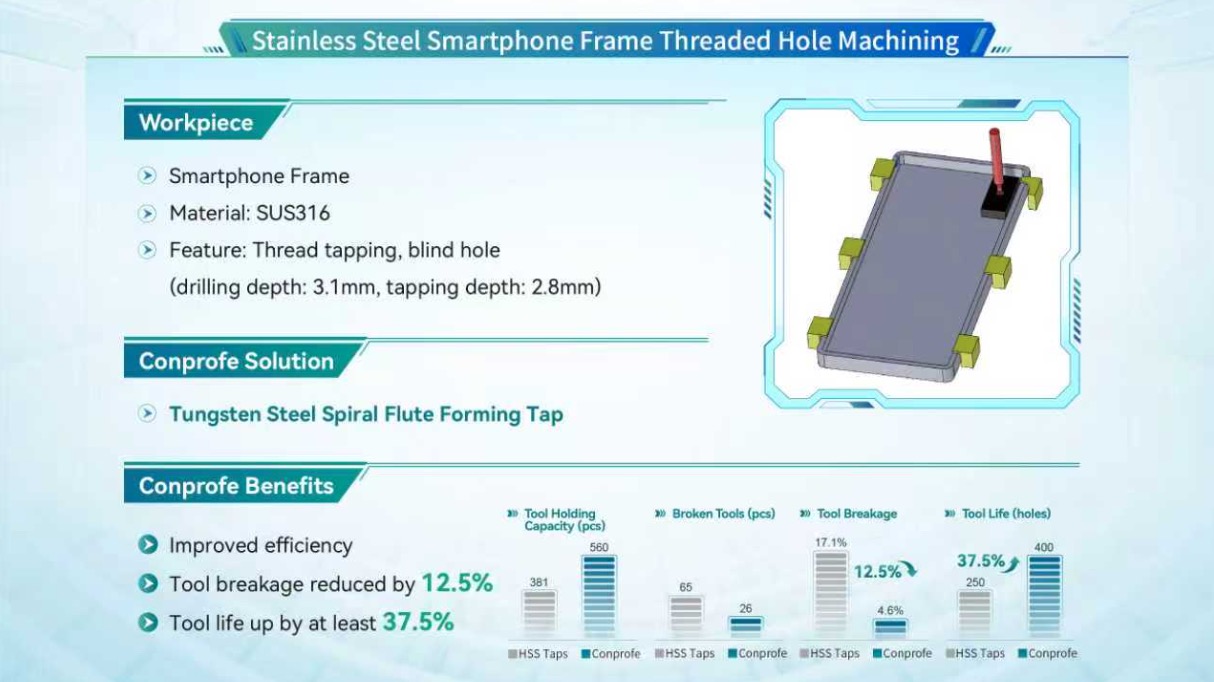

See the difference in action with our Tungsten Steel Spiral Flute Forming Tap when machining threads in tough SUS316 stainless steel smartphone frames. This solution integrates tapping and drilling for blind holes, dramatically boosting efficiency. Tests report a 12.5% reduction in tool breakage and a remarkable 37.5% increase in tool life, translating directly to lower costs and higher productivity.

Ready to elevate your micro-tapping process? Follow Conprofe for more insights and discover how our forming tap solutions can drive efficiency and quality in your production line.