Conprofe Launches Pioneering “Dual Ultrasonic-Green” Machining Solution at CIMT Beijing

May 6, 2025 5:40 pm

May 6, 2025 5:40 pm

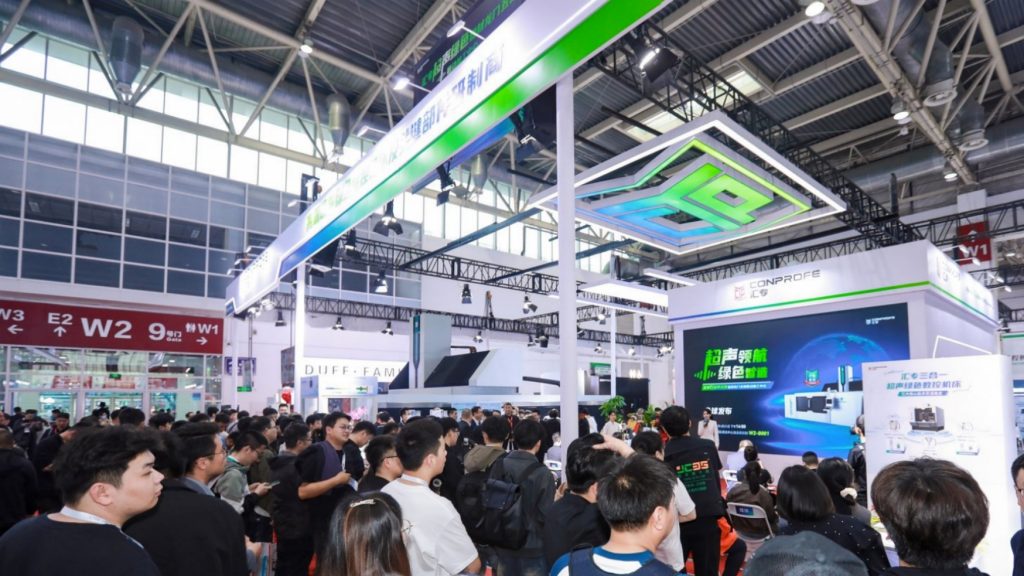

The 19th China International Machine Tool Show (CIMT 2025), the world’s premier machine tool exhibition, concluded successfully in Beijing on April 26. We participated in the exhibition with our full range of Ultrasonic-Green CNC Machining Solutions and unveiled our latest innovation – the “Conprofe Dual Ultrasonic-Green 5-Axis Gantry Machining Center” – to global manufacturers. Throughout the event, our 800sqm booth W2-B001 has attracted significant attention from domestic and overseas visitors in the high-end manufacturing industry, with numerous inquiries and signed agreements marking a productive engagement.

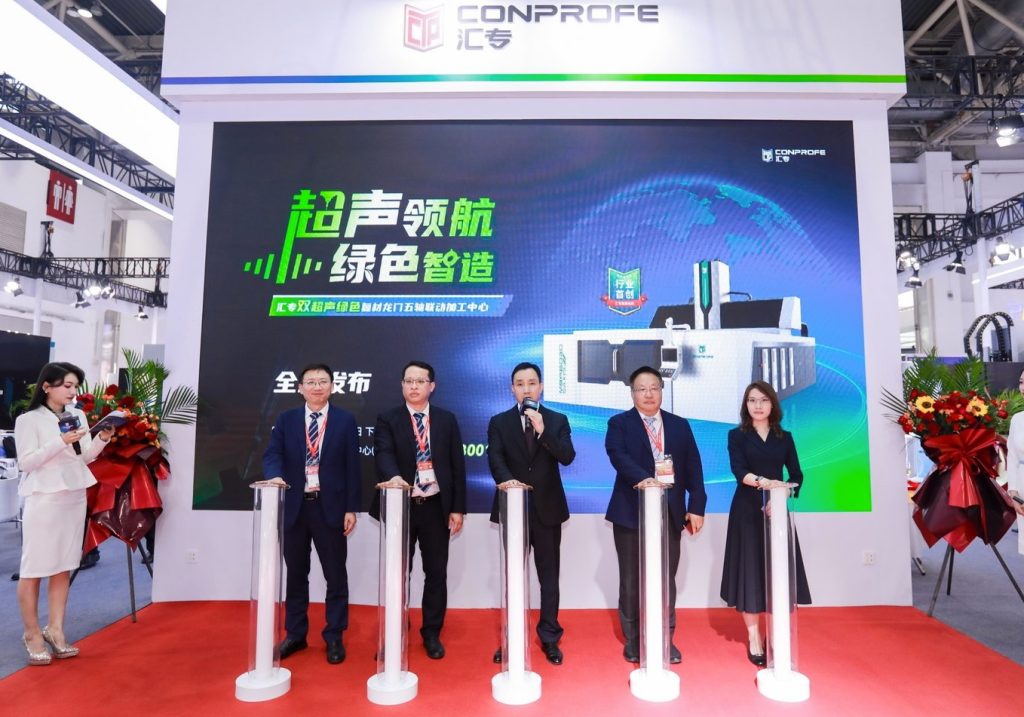

The Global Launch of Conprofe Dual Ultrasonic-Green 5-Axis Gantry Machining Center

On the opening day, we hosted a global launch event to introduce our latest breakthrough in composites machining – the Conprofe Dual Ultrasonic-Green 5-Axis Gantry Machining Center MBR6030-5AXIS. This gantry machine is designed to tackle industry bottlenecks of machining various composites in the aviation industry. It is equipped with dual-ultrasonic machining systems and dual-green cooling systems. While the industry is struggling to use two milling heads or two spindles to switch between composite cutting and milling, our MBR6030-5AXIS realizes automatic tool changing with only one single spindle, which leads to significant cost saving, process streamlining, efficiency and yield improvement. Furthermore, it offers supercritical CO2 cryogenic cooling and cryogenic air blasting options, boosting productivity in a sustainable way. This innovation underscores our leadership in High-End CNC Ultrasonic-Green Machine Tools.

The launch event also garnered coverage in the CIMT official newspaper and was featured by multiple domestic media outlets.

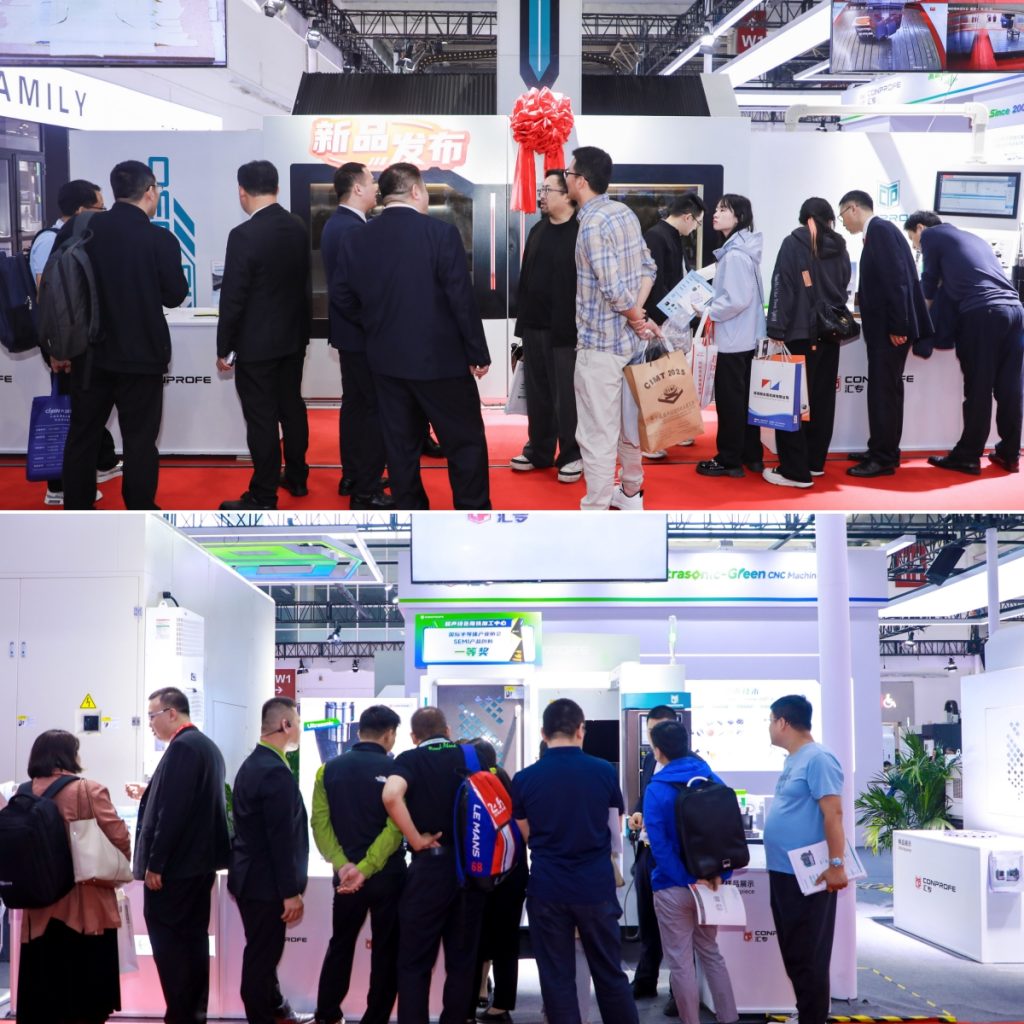

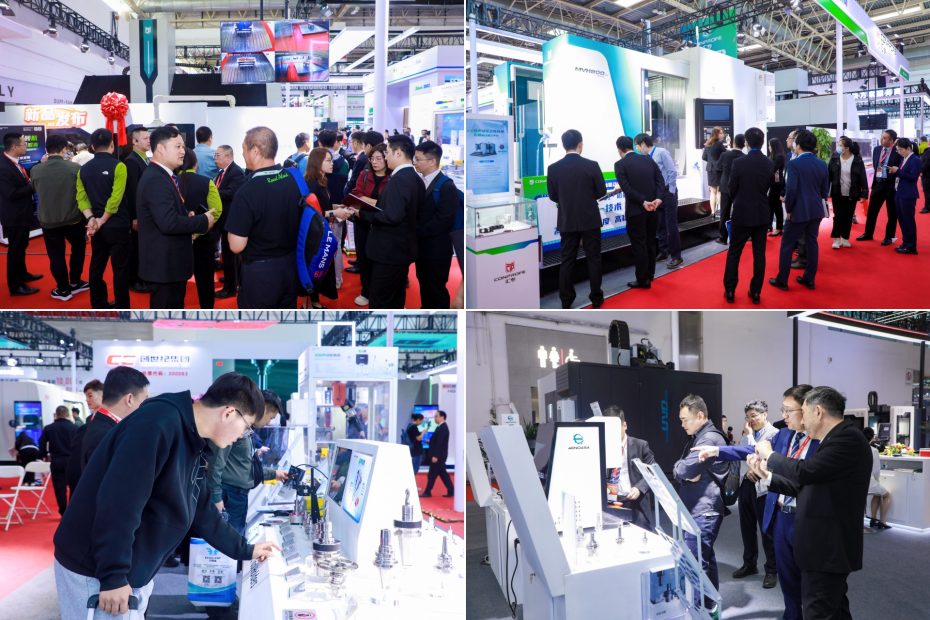

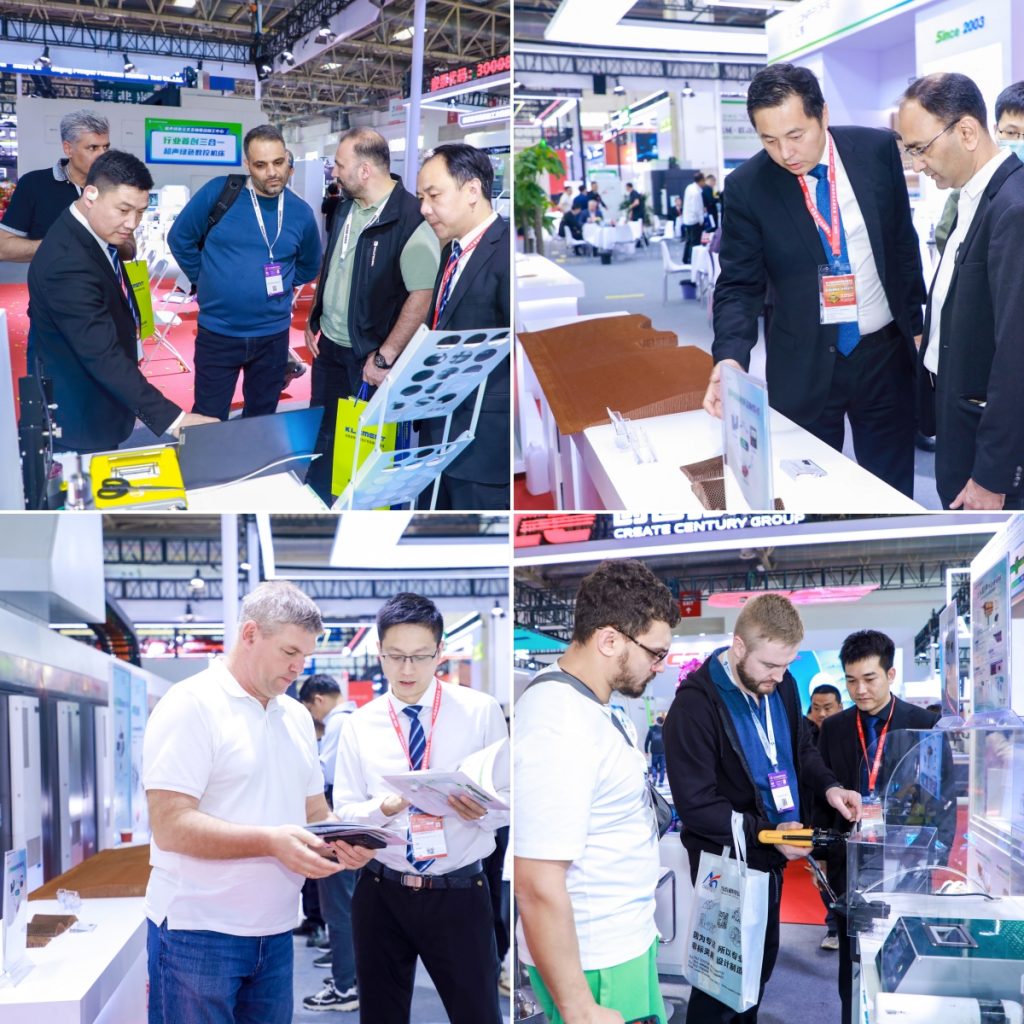

A Comprehensive Display of Innovative CNC Solutions

At the exhibition, we presented a full spectrum of products, ranging from part & unit level to machine-level solutions. Highlights included 12 Ultrasonic-Green CNC Machine Tools, such as the newly launched 5-axis gantry machining center, vertical 5-axis machining center, engraving and milling center, graphite machining center, lightweight vertical 5-axis machining center, and vertical-horizontal 5-axis machining center, etc. Additionally, the key parts and units – including ultrasonic cutting systems, ultrasonic pneumatic drills, ultrasonic tool holders, super-hard & solid carbide cutting tools, shrink-fit units, and press-fit units – drew significant interest from attendees. One of the flagship exhibits was the Ultrasonic Engraving and Milling Center UEM-600, the winner of the SEMICON Innovation Award. It features a 50,000rpm ultrasonic spindle and excels in machining semiconductor hard-brittle materials like quartz glass, silicon carbide, and silicon nitride. It achieves ultra-deep micro-hole drilling (D0.45mm, depth-diameter ratio of 55:1) in single-crystal silicon curved electrodes, surpassing EDM, laser, and conventional CNC in efficiency and quality, driving strong demand from global semiconductor clients.

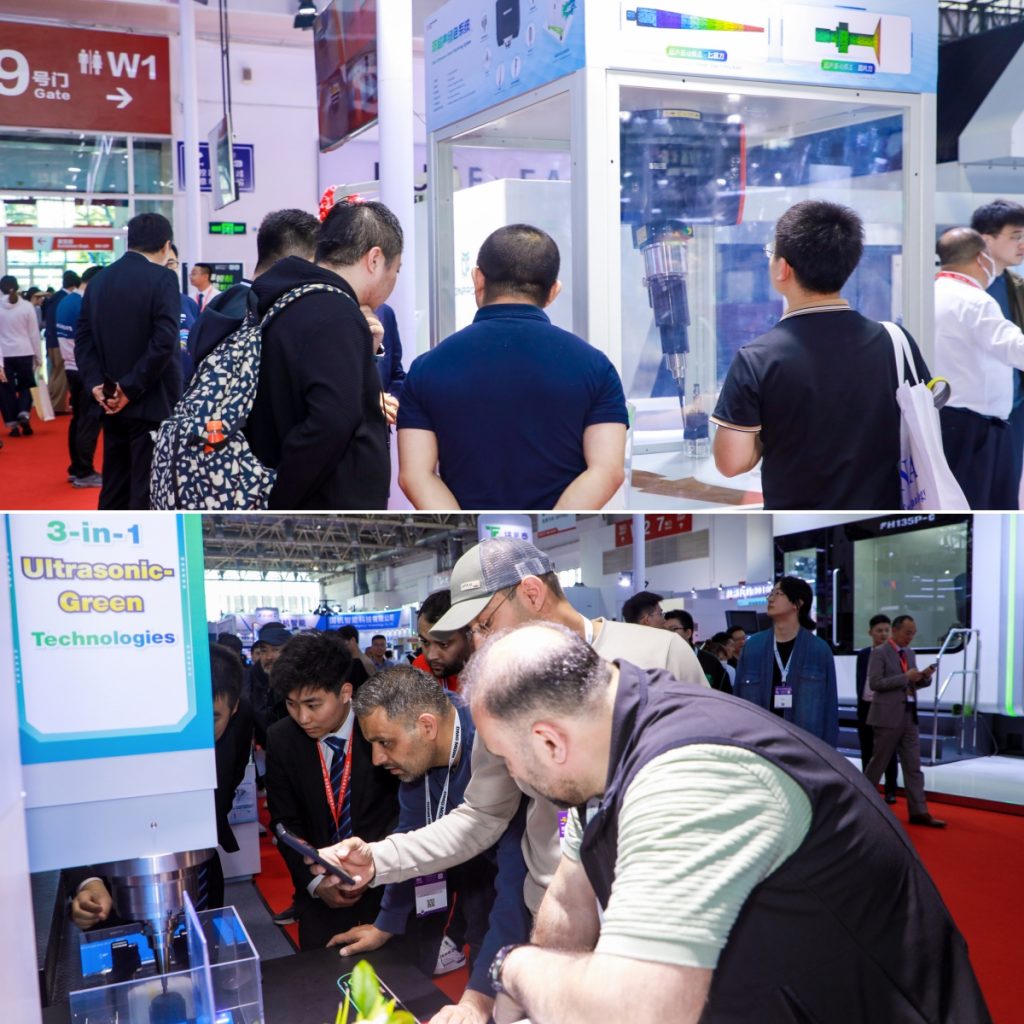

Interactive Demonstrations of Ultrasonic Machining Technology

To provide hands-on experience, we set up dedicated demonstration zones for our Dual Ultrasonic-Green Machining System and 3-in-1 Ultrasonic-Green Technologies, alongside four interactive zones for honeycomb core cutting, ultrasonic drilling, ultrasonic vibration, and micro hole observation. These areas allowed visitors to observe the advantages of ultrasonic technology in 3+A applications – machining hard-brittle materials, composites and hard-to-cut metals, as well as superior hole drilling in all materials.

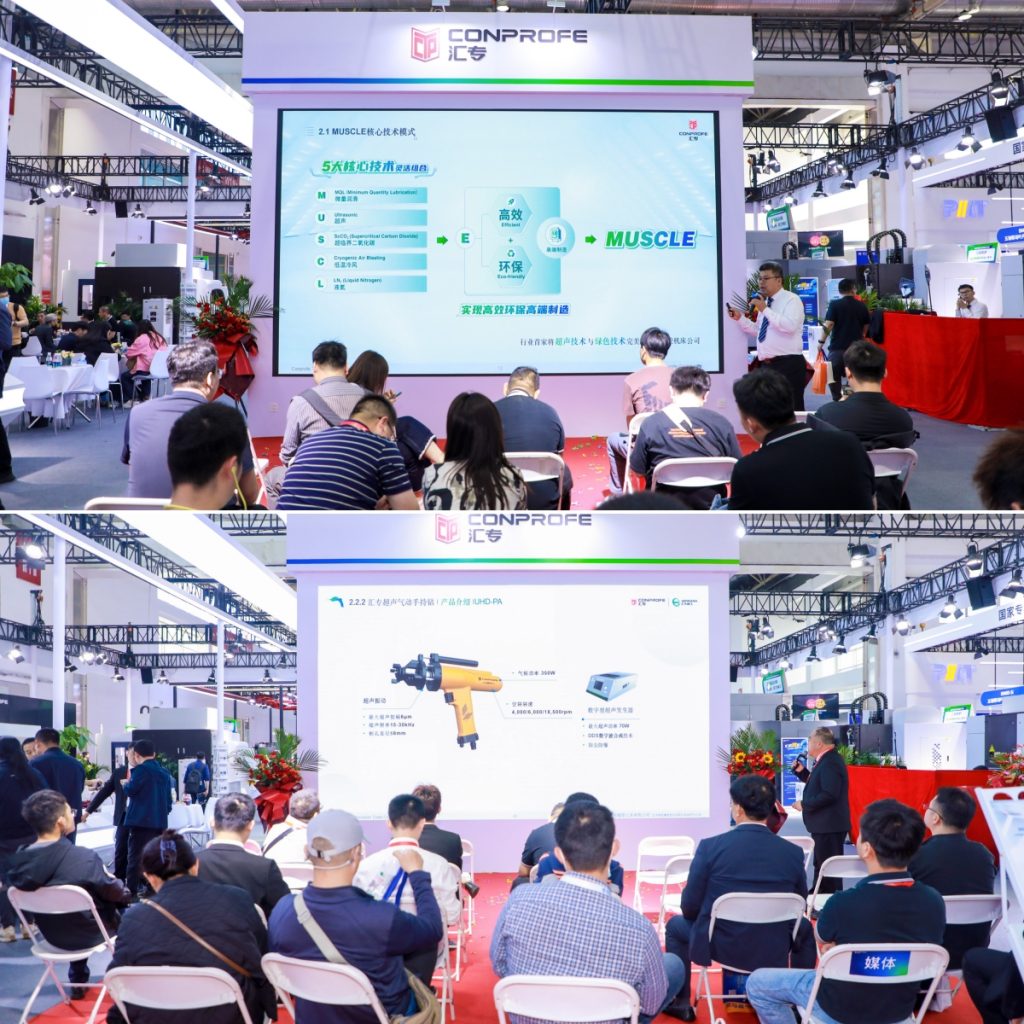

Keynote Speeches for Industry-Specific Applications

Complementing the product displays, we also organized several keynote speeches on core technologies and innovative applications across key industries, including aviation, semiconductors, medical field, automotive, and consumer electronics. Industry experts discussed the latest trends in efficient, green, and intelligent machining, aligning with the shared goal of overcoming sector-specific manufacturing challenges.

Three Strategic Partnerships Forged and Two Machine Tools Sold

The exhibition also served as a platform for fostering international collaborations. From April 23 to 24, we established strategic cooperation agreements and sales contracts with our regional agents: Taiwan’s LiFu Co. and Road Ahead Technologies Consultant Corp. (RATC), and Malaysia’s Maxeffect Resources (Juru) Sdn. Bhd. These partnerships will focus on the distribution and promotion of Conprofe’s Ultrasonic-Green CNC Machine Tools and Key Units in key regional markets. Two machine tools were sold right on site, demonstrating the immediate confidence of our clients in our CNC machines. We also fostered cooperation with agents from France, Italy, Turkey, Japan, South Korea and Singapore, marking a significant step in accelerating our global expansion.

Conprofe’s Ultrasonic-Green Machining Solutions revolutionize CNC technology, delivering a generational leap in ultrasonic machining. With globally patented ultrasonic spindles and an intelligent CNC system featuring amplitude closed-loop and adaptive control, they ensure exceptional accuracy and stability. These solutions offer efficient, eco-friendly options for machining challenging materials.

With the successful conclusion of CIMT 2025, Conprofe remains committed to advancing Ultrasonic-Green Technology and delivering high-efficiency, sustainable, and intelligent machining solutions. By driving innovation in the global machine tool industry, we aim to support the ongoing transformation and upgrading of manufacturing worldwide.