▪ RTCP tip follow

▪ A clamping, multi – sided processing

▪ The best choice for complex surface machining

Machining Centers

▪ Repeatability of 4μm ▪ High rigidity beam column integrated casting structure ▪ Both applicable to dry cutting and wet cutting

Milling Centers

▪ Repeatability of 4μm

▪ High rigidity beam column integrated casting structure

▪ Both applicable to dry cutting and wet cutting

Besides bringing economic benefits like shorter cycle time, longer tool life and better surface quality, Conprofe also endeavors to forge a more environmental-friendly way of machining by replacing flood coolants with its Ultrasonic-Green Machine Tools, which are widely used in consumable electronics, semiconductors, automotive, aerospace, medical, general precision manufacturing industries.

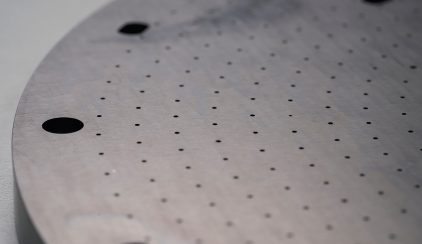

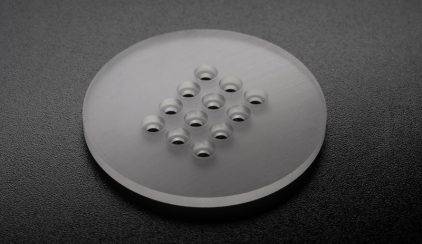

Single-Crystal Silicon Showerhead Micro-hole Drilling

Results and Benefits:

+ Hole edge chipping <0.03mm

+ Hole position accuracy <0.01mm

+ Achieve micro-hole drilling (D0.48x18mm)

+ Tool life >1,000 holes

Related Case

Aluminum Alloy Blisk 5-Axis Simultaneous Machining

Results and Benefits:

+ Good surface quality

+ High precision and high efficiency for complex machining

+ The thinnest part of the blade is only 0.5mm, no deformation and uniform gauge

Related Case

Titanium Alloy Lumbar Fusion Cage Machining

Results and Benefits:

+ Machining efficiency up by 20%

+ Tool life up by 50%+

+ Surface roughness Ra<0.6μm

+ Burrs significantly reduced

+ Green machining

Related Case

Aluminum Laptop Cavity Machining

Results and Benefits:

+ Big-volume roughing with max. Ap 4.6mm

+ Cost-saving and environmental-friendly machining

Related Case

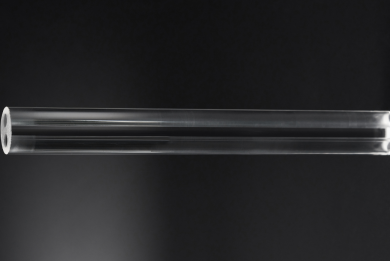

Quartz Glass Fiber Preform Pre-stressed Hole Machining

Results and Benefits:

+ Hole wall roughness between Sa 0.122-0.232μm by ultrasonic machining

+ Parallelism of the two holes <0.0385mm, meeting customer’s drawing requirements

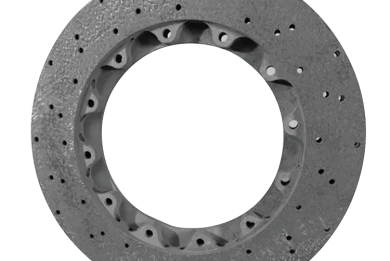

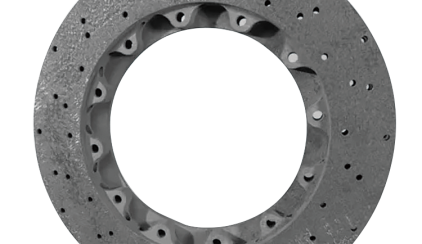

Carbon-Ceramic Composite Material New Energy Vehicle Brake Disc Machining

Results and Benefits:

+ No obvious chipping, cracks, layering, drawing and other undesirable phenomena, no burrs on workpiece surface

+ Ultrasonic machining time is 48min, efficiency up by 46.67%

Related Case

Quartz Glass Showerhead

Silicon Carbide Showerhead

Single-Crystal Silicon Showerhead

Single-Crystal Silicon Showerhead

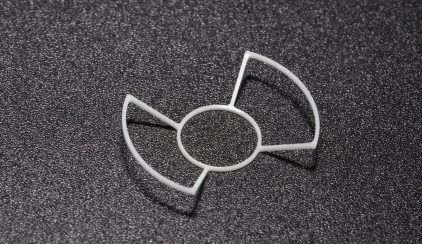

Zirconia Ceramic Aviation Inclined Support Ring

Quartz Glass Hemispherical Resonator Gyroscope (HRG)

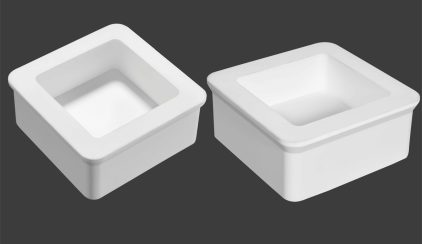

Quartz Ceramic Antenna Box

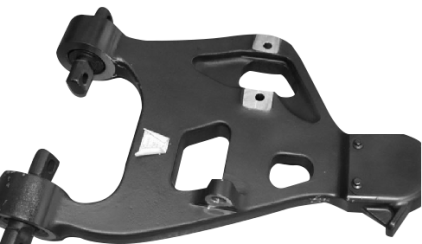

Titanium Alloy TC4 Vehicle Steering Damper Bracket

PEEK Cervical Fusion Cage

Titanium Alloy TC4 Cervical Spine Plate

UHMWPE Shin Pad

Titanium Alloy for 3D Printing Artificial Skull

Related Case

Aluminosilicate Glass

Sapphire Through-hole

Titanium Phone Enclosure

Titanium Tablet Enclosure

Silicon Carbide Chucks

Silicon Carbide Chucks

CONPROFE COMPETITIVE ADVANTAGES

Advanced Technologies

Innovative solutions for hard-to-cut materials through its CNC machines equipped with Rotary Ultrasonic Machining (RUM) and MQL/ScCO2 cooling technologies

Experience

Over 20 years, Conprofe’s R&D team has developed 850+ technology patents for its advanced Ultrasonic-Green Machine Tools

GET FREE QUOTES

COMPANY INTRODUCTION

- For more than 20 years, Conprofe has strived to differentiate itself from its many machine tool manufacturing peers by developing its unique machining centers and innovative solutions for hard-to-cut advanced materials through its patented Rotary Ultrasonic Machining (RUM) and MQL/ScCO2 cooling technologies.

- Besides bringing economic benefits like shorter cycle time, longer tool life and better surface quality, Conprofe also endeavors to forge a more environmental-friendly way of machining by replacing flood coolants with its Ultrasonic-Green Machine Tools, which are widely used in consumable electronics, semiconductors, automotive, aerospace, medical, general precision manufacturing industries.

Agents Wanted

welcome to join us!

NEWS

South Korea’s Carbon Fiber Industry: A Global Leader in Innovation & Sustainability

Exciting insights from the recent article “Advancing Carbon Fiber and its Composites Technology: Korea’s Strategic

Conprofe Launches Pioneering “Dual Ultrasonic-Green” Machining Solution at CIMT Beijing

The 19th China International Machine Tool Show (CIMT 2025), the world’s premier machine tool exhibition, concluded successfully

Conprofe Unveils Dual Ultrasonic-Green 5-Axis Gantry Machining Center at CIMT Global Launch

On April 21, 2025, the 19th China International Machine Tool Show (CIMT 2025) commenced