Superalloy Blade Cooling Holes Machining

Conprofe Benefits

✅ Lower cutting force and significant burr reduction

✅ Qualified hole dimensional accuracy

✅ Hole wall roughness decreased by 88%, from 1.629μm to Ra 0.181μm

✅ Cycle time shortened by 40%

Superalloy Blisk Machining

Conprofe Benefits

✅ Reduced cutting force and improved surface quality

✅ Blade roughness reduced by 56%, from Sa 0.93μm to Sa 0.408μm

Stainless Steel Flight Engine Chiller Hole Drilling

Conprofe Benefits

✅ Cycle time down by 31.8%

✅ Tool life up by 63 times to 3,180 holes/tool

✅ Qualified hole dimensional accuracy

Titanium Alloy Hole Drilling

Conprofe Benefits

✅ Cycle time shortened by 49%

✅ Qualified hole wall roughness Ra 0.24μm

✅ Machining efficiency and yield improved

Superalloy Side Milling

Conprofe Benefits

✅ Lower cutting force and reduced tool wear with ultrasonic machining

✅ Machining length per tool increased by 33% to avg. 80 meters

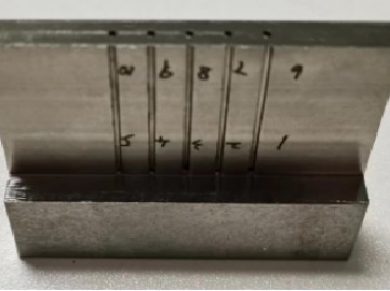

Superalloy Cotter-Pin Hole Drilling

Conprofe Benefits

✅ Hole wall quality improved

✅ Burrs reduced by 91.6%, from 1.206mm to 0.101mm

✅ Cost saving from replacing manual operation with CNC machining

Aluminum Silicon Carbide Hole Drilling & Thread Machining

Conprofe Benefits

✅ No cracks or chippings

✅ Tool life up by 800 times, from less than one hole to over 200 holes

✅ Significant cost saving from replacing manual operation with CNC machining

AlSiC Braking Disc Hole Drilling

Conprofe Benefits

✅ No burrs or flanging at hole edges

✅ Tool life improved by 9 times to 50 holes/tool

✅ Cycle time shortened by 51%, from 530s to 260s per hole