Graphite Mold Flat Machining

Benefits

✅ Surface roughness down by 81%, from 744nm to 139 nm

✅ Tool life increased by 3 times

Silicon Nitride Plate Cover & Cavity Machining

Benefits

✅ Cutting force reduction with ultrasonic machining

✅ Chipping decreases from 0.229mm to 0.02mm, 91%

✅ Significant improvement in roughness and yield

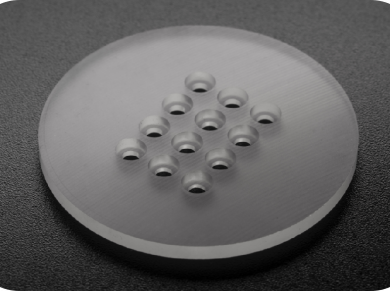

Sapphire Through-Hole Sidewall Machining

Benefits

✅ Hole wall roughness improved from by 85%, 293nm to 46nm

✅ No need for polishing

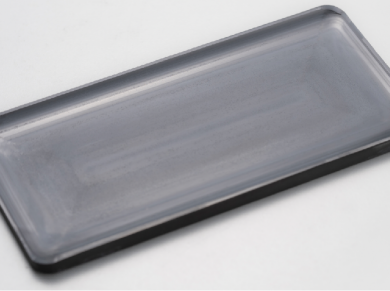

Curved Surface Machining of Aluminosilicate Glass

Conprofe Benefits

✅ Lower surface roughness

✅ Cutter profile tolerance consistently within 0.01mm, facilitating stable mass production and reduced polishing

✅ 14 times tool life increase, from 100 to 1500 pieces

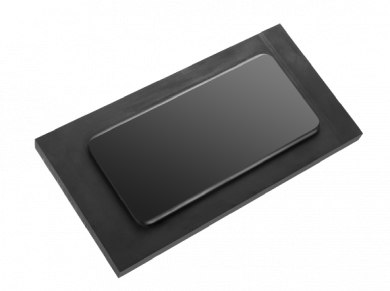

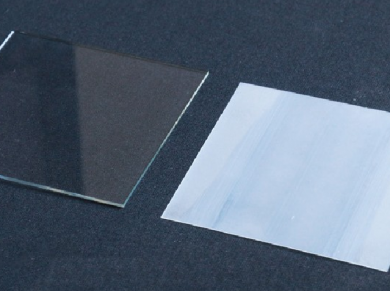

Ultra-thin Glass Flat Surface Machining

Benefits

✅ Surface roughness Sa down by 52%, from 531nm to 254nm

✅ No cutter marks or cracks

Titanium Alloy Phone Enclosure Side Milling

Conprofe Benefits

✅ Tool life doubled

✅ Surface roughness down by 50%

✅ Burr reduction and lower manual deburring costs

✅ Clean machining without cutting fluids

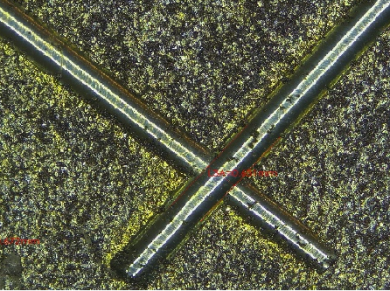

Forged Titanium Alloy Deep Blind Cross-Hole Drilling

Conprofe Benefits

✅ Cycle time down by 73%, from 55 seconds to 15 seconds

✅ Smooth hole wall without discoloration

✅ No observable burrs and no need for manual deburring