Core Technologies of Conprofe’s Ultrasonic Machining

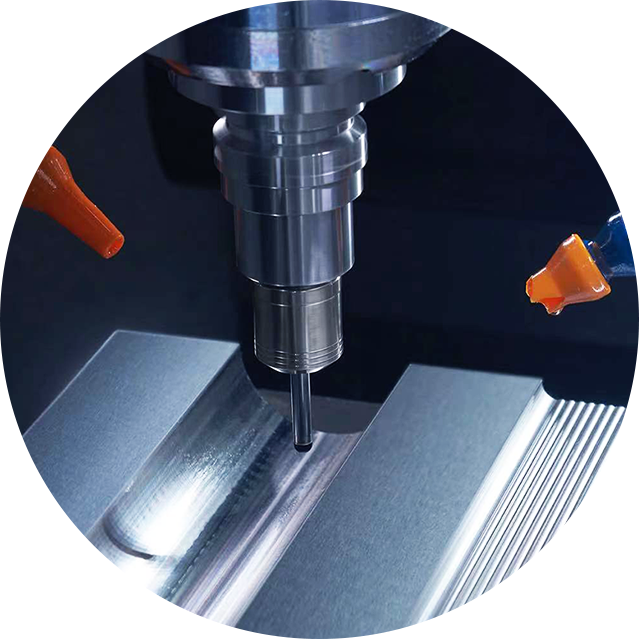

As the a top CNC machine tool manufacturer, Conprofe takes the lead in organic integration of ultrasonic technology and green technology. Our breakthroughs in ultrasonic machining technology empower us to overcome the challenges associated with processing hard and brittle materials, as well as hard-to-cut metal materials. This has led to the development of our ultrasonic machine tools with independent intellectual property rights.

Among them, Ultrasonic Machining Technology, Minimum Quantity Lubrication and Supercritical CO2 Cooling Technology are included in Ultrasonic and Green Technologies. When applied to actual machining requirements, Ultrasonic Technology and Green Technology can improve machining efficiency, prolong tool life improve workpiece surface roughness, reduce burrs and achieve clean cutting.

The cutting-edge ultrasonic machining system with the CNC cooling system, together, boast a minimum of 0.01mm of blade width, tool profile accuracy ≤3μm, long tool life, and the ability to improve workpiece surface quality, self-developed products of the Solid PCD Micro-Edge Cutting Tool has obtained international patents.

FAQs of Ultrasonic Machining

- What is ultrasonic machining, and how does it differ from traditional machining methods?

Ultrasonic machining is an advanced manufacturing process that utilizes ultrasonic vibrations to remove material from workpieces. Unlike traditional machining methods that rely solely on mechanical forces, ultrasonic machining tool technology enhances precision and efficiency by harnessing the power of ultrasonic waves to achieve intricate cuts.

- How does an ultrasonic CNC machine enhance machining capabilities?

A CNC ultrasonic machine integrates ultrasonic technology with computer numerical control (CNC), allowing for precise control and automation of the machining process. This combination enables operators to achieve high levels of accuracy and repeatability, making it ideal for complex precision machining tasks.

- What are the key features of a rotary ultrasonic machiningsystem?

A rotary ultrasonic machining system utilizes both rotational and ultrasonic motion to improve material removal rates and surface finish quality. By combining these two actions, rotary ultrasonic machining tool technology enhances efficiency and productivity, especially in applications requiring intricate shapes and tight tolerances.

- How can an ultrasonic cutting machinebenefit my manufacturing process?

An ultrasonic cutting machine offers several advantages, including reduced heat generation, minimal tool wear, and enhanced precision. This makes it particularly suitable for machining hard and brittle materials where traditional cutting methods may be ineffective or cause damage.

- What factors should I consider when choosing an ultrasonic machining toolfor my application?

When selecting an ultrasonic machining tool, it’s essential to consider factors such as material type, desired surface finish, dimensional accuracy requirements, and production volume. Additionally, evaluating the compatibility of the tool with your existing CNC systems can ensure seamless integration and optimal performance.