単結晶シリコン曲面電極穴開け加工

加工の優位性

✅ PCDドリルはD0.45*24.75mmの微細超深穴を連続で2000個加工できる(アスペクト比55:1)

✅ ブラインド穴加工、穴の入口部はチッピングがないと目視で確認できる

✅ 穴の真円度が0.003㎜

✅ 穴壁の粗さは6.540μmから0.013μmへと99.8%低減

石英ガラススプレープレートの穴あけ加工

加工の優位性

✅ D0.5x5mmの穴を1,200個安定して連続的に加工可能(アスペクト比10:1)

✅ 穴一個当たりの加工時間は270秒から75秒まで72%短縮

✅ 穴壁が滑らかで、穴の開口部のチッピング量は0.4㎜から0.13mmへと68%減

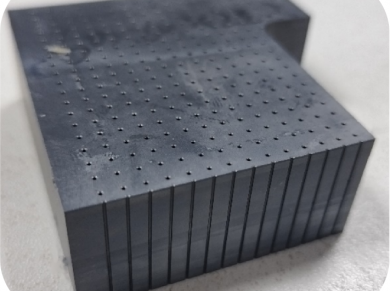

炭化ケイ素スプレープレートの穴あけ加工

加工の優位性

✅ D0.5×6.5mmの穴を100個安定して連続的に加工

(アスペクト比13:1)

✅ 穴壁が滑らかであり、穴の開口部のチッピングが0.02mm以下

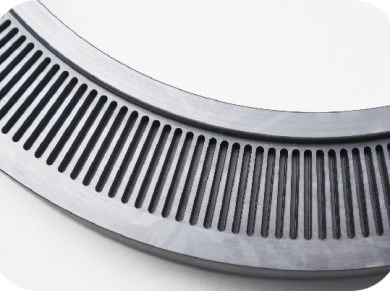

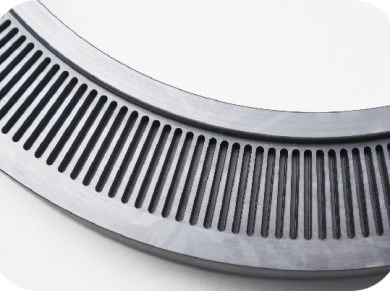

ポリシリコンゲートリング加工

加工の優位性

✅ 超音波補助加工がより安定し、切削抵抗が低いため、加工効率が向上

✅ ワーク表面の粗さが低減

✅ 欠けやひび割れが低減

✅ 内円の真円度が効果的に向上

Polysilicon Slotted Confinement Ring

Conprofe Benefits

✅ Reduced cutting force and improved efficiency with ultrasonic machining

✅ Lower surface roughness

✅ Reduced chipping or crack

✅ Improved hole roundness

Carbon Silicon Showerhead Hole Drilling

Conprofe Benefits

✅ Continuously machining over 100 D0.5×6.5mm holes

(Depth-Diameter Ratio 13:1)

✅ Smooth hole wall and good hole quality (Hole chipping size <0.02mm)

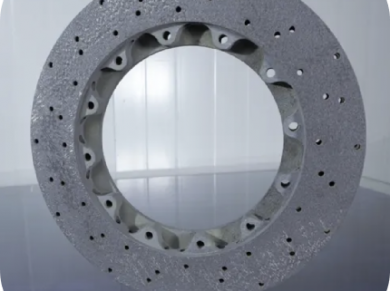

Carbon-Ceramic Brake Machining

Benefits

✅ Improved surface quality with no obvious clipping, cracking, delamination or fiber pull-out

✅ Cycle time down by 47%, from 120 min to 64 min

Quartz Glass Optical Fibers Deep Hole Drilling

Conprofe Benefits

✅ Hole wall roughness 0.122~0.232μm with ultrasonic machining

✅ Hole parallelism <0.0385mm (vs. required<0.8μm)