Superalloy Blade Cooling Holes Machining

Benefits:

+ Lower cutting force and significant burr reduction

+ Qualified hole dimensional accuracy

+ Hole wall roughness decreased by 88%, from 1.629μmto Ra 0.181μm

+ Cycle time shortened by 40%

AlSiC Braking Disc Hole Drilling

Benefits:

+ No burrs or flanging at hole edges

+ Tool life improved by 9 times to 50 holes/tool

+ Cycle time shortened by 51%, from 530s to 260s per hole

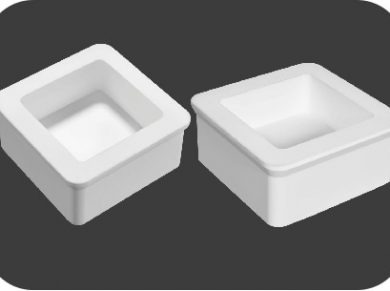

Quartz Ceramic Antenna Box Machining

Benefits:

+ Significant cutting force reduction with ultrasonic machining

+ Minimized cracks and chippings

+ Cycle time shortened by 75%, from 660min to 165min

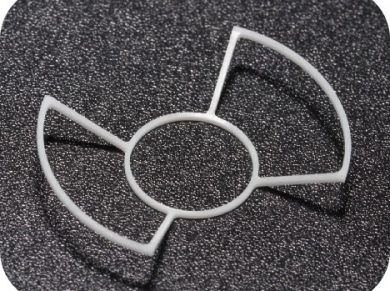

Zirconia Ceramic Aircraft Supporting Ring

Benefits:

+ Lower cutting force, reduced sub surface damage (SSD) and cracks

+ Minimized surface carbonization with picosecond laser cutting

Alumina Ceramic Impeller Machining

Benefits:

+ Longer tool life and higher contour accuracy with ultrasonic machining

+ Reduced SSD and chippings

+ Polishing time shortened from improved surface quality

Carbon-Carbon Composite Hole Threading

Benefits:

+ Qualified thread quality

+ Replacing manual operation with CNC thread milling

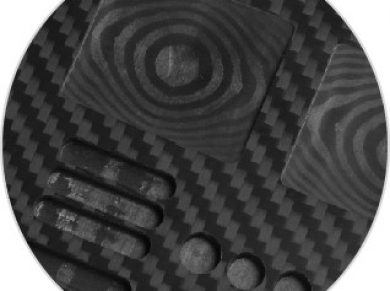

Carbon Composites Blind-Groove & Cavity Milling

Benefits:

+ Improved surface quality

+ Stable and high-precision machining

+ Blind groove roughness down by 75%

+ Cavity roughness down by 60%

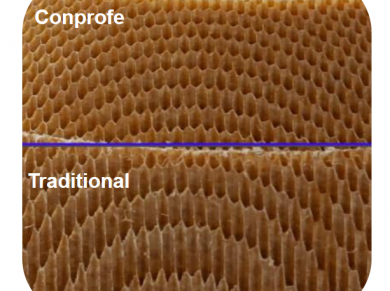

Nomex Honeycomb Contouring

Benefits:

+ Burr reduction by 90%

+ Efficient 5-axis contouring of complicated shapes

+ Optional fully-closed protection and vacuum system against dust and explosion