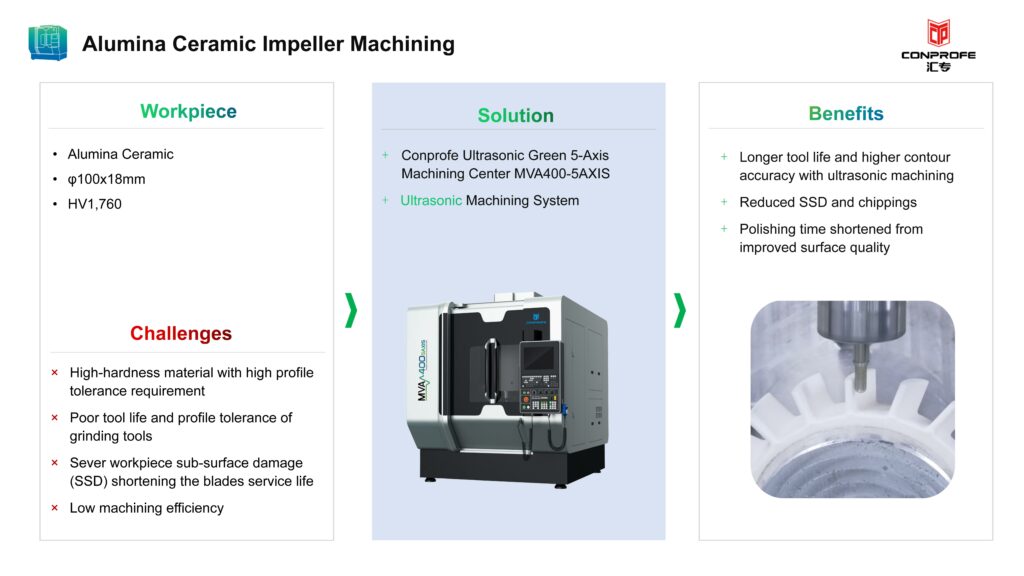

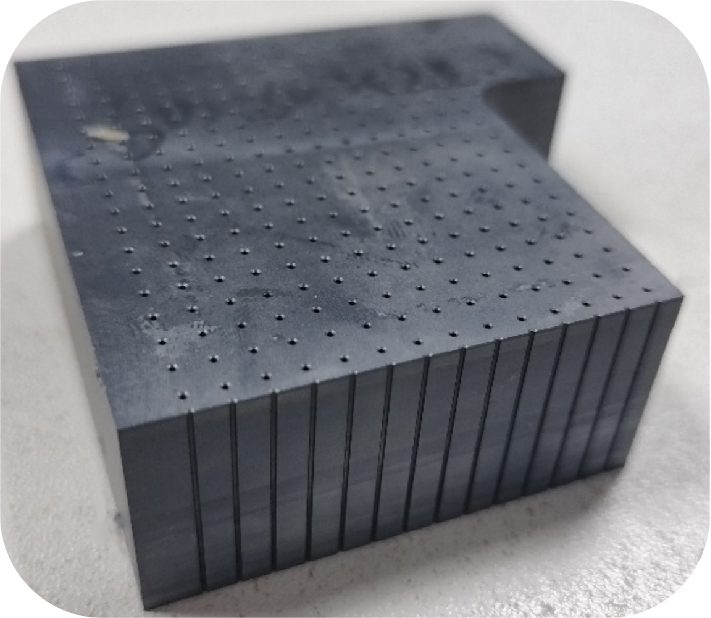

Workpiece

- Alumina Ceramic Impeller

- φ100x18mm

- HV1,760

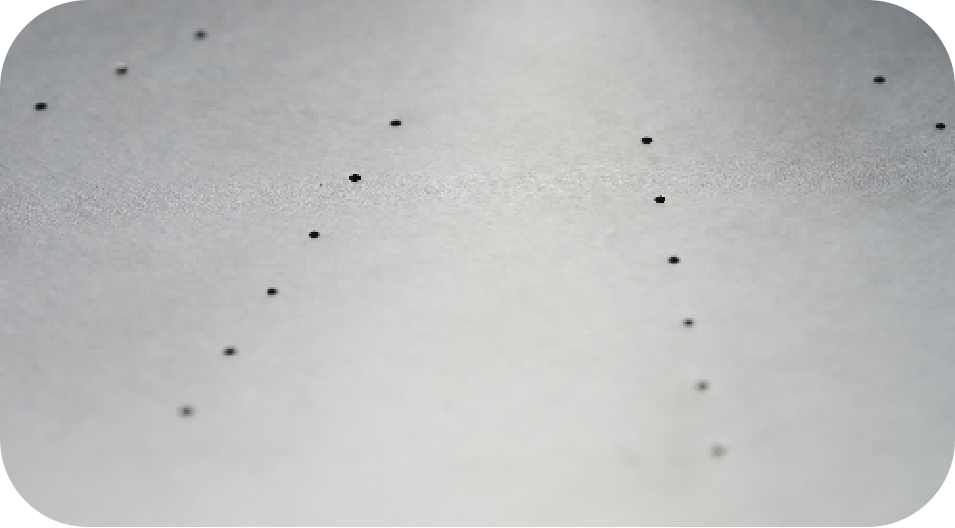

Challenges

- High-hardness material with high profile tolerance requirement

- Poor tool life and profile tolerance of grinding tools

- Sever workpiece sub-surface damage (SSD) shortening the blades service life

- Low machining efficiency

Benefits

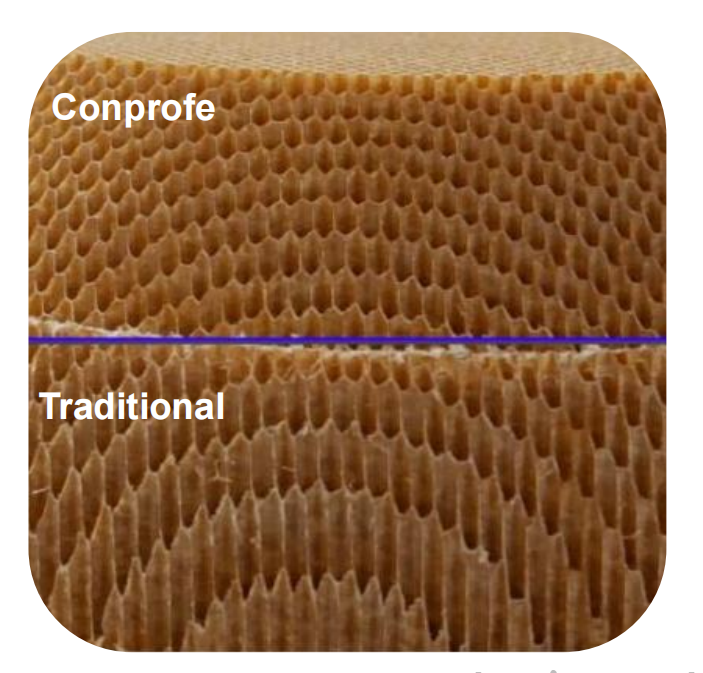

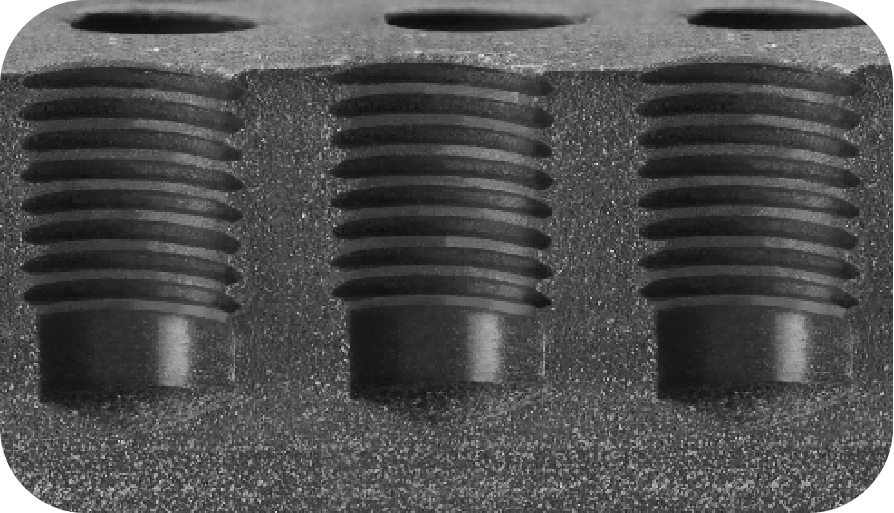

- Longer tool life and higher contour accuracy with ultrasonic machining

- Reduced SSD and chippings

- Polishing time shortened from improved surface quality