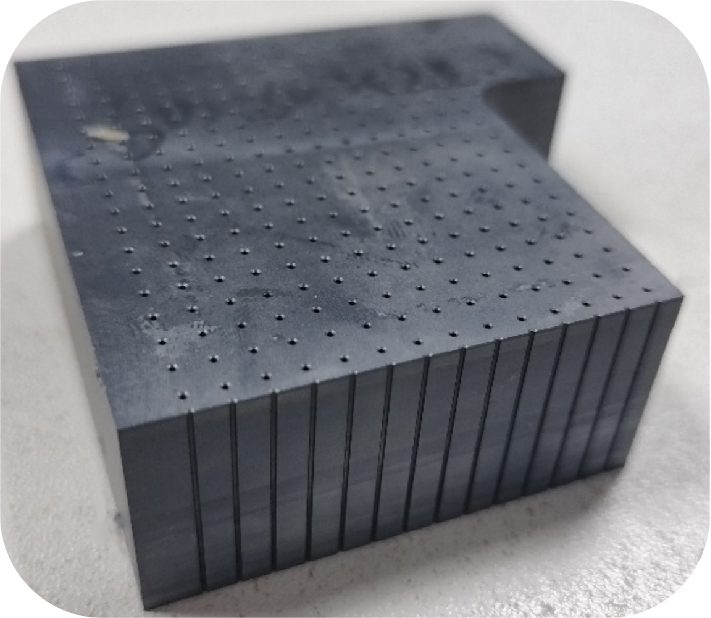

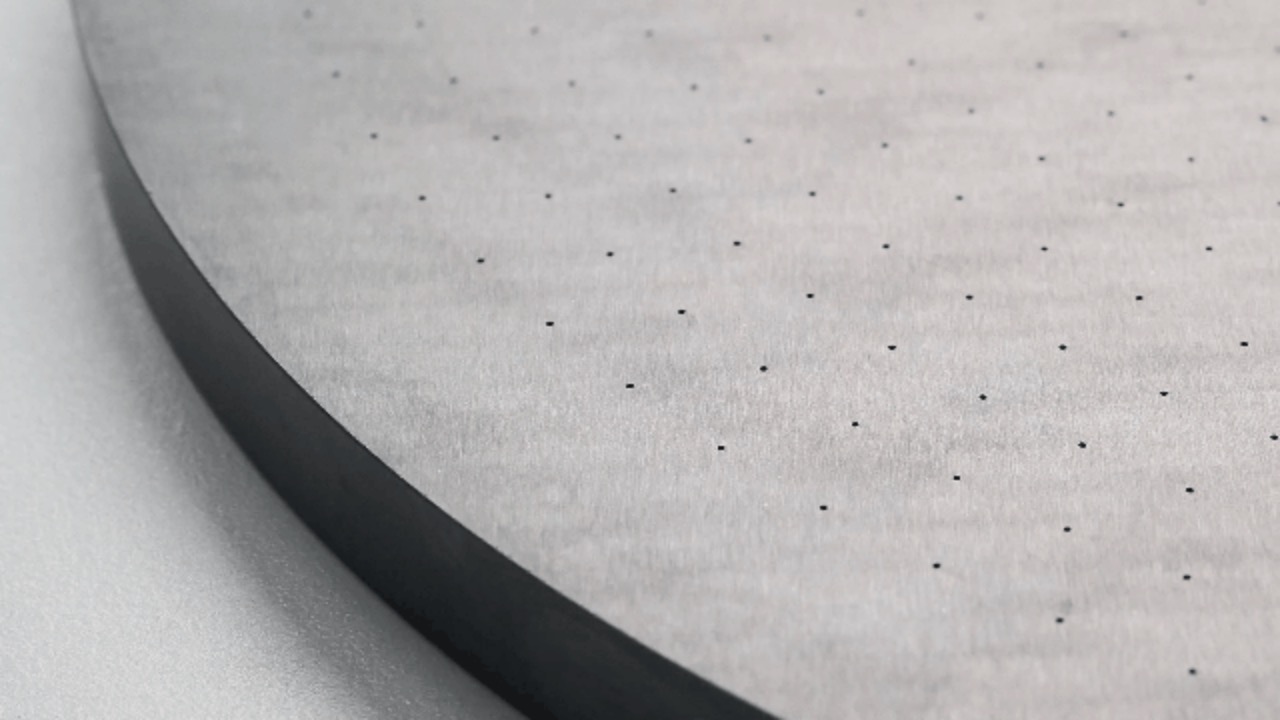

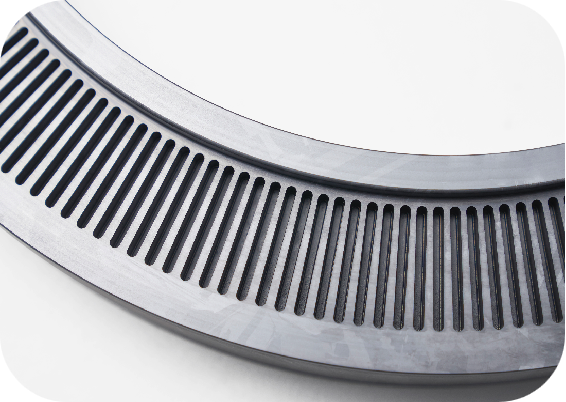

Workpiece

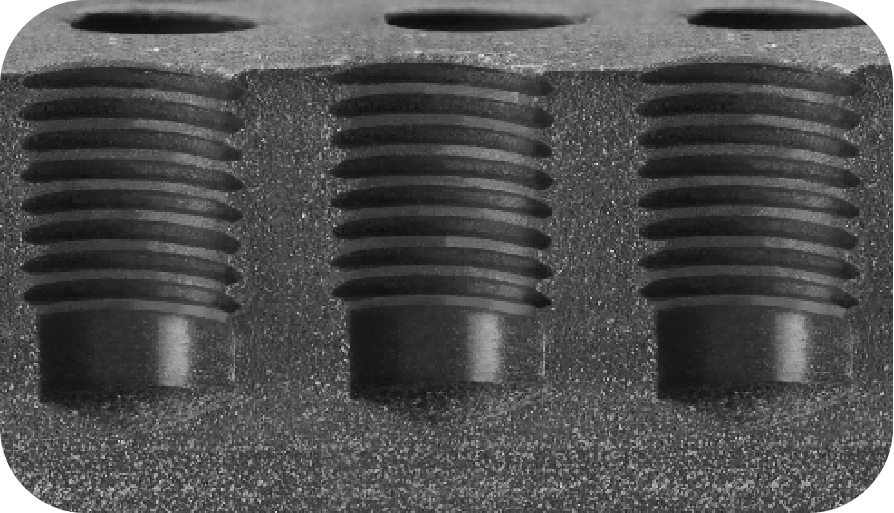

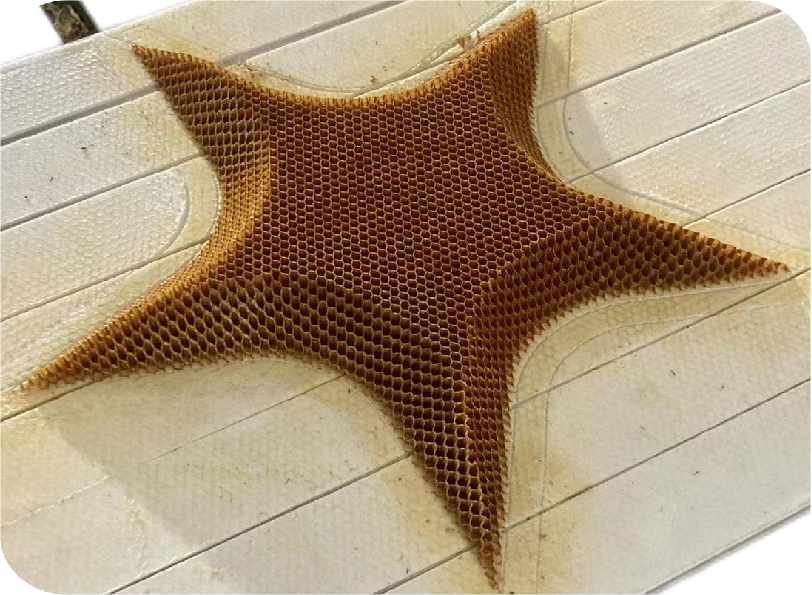

🔔 AlSiC workpiece (60% SiC)

🔔 M3x6mm Thread Holes

Challenges

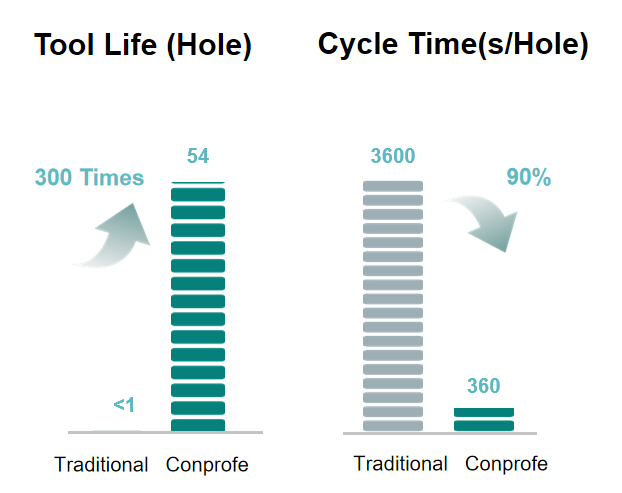

❌ Long cycle time with manual tapping: 3,600s+

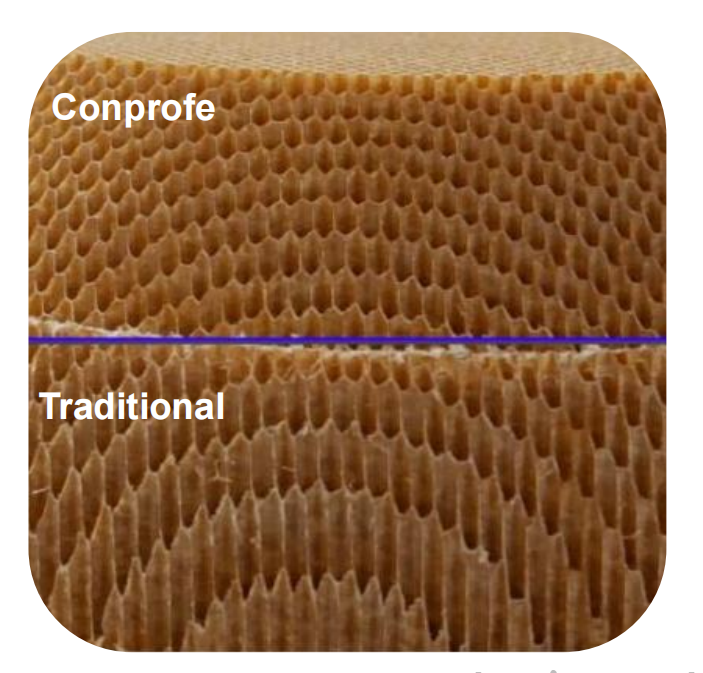

❌ High scrap rate from poor thread quality

❌ 6 taps needed to machine one hole

❌ Manual operation

Conprofe Benefits

✅ Tool life improved by 300 times (54 holes/tool)

✅ Cycle time shortened by 90%, from 3600s/hole to 360s/hole

✅ Replacing manual operation to CNC thread milling