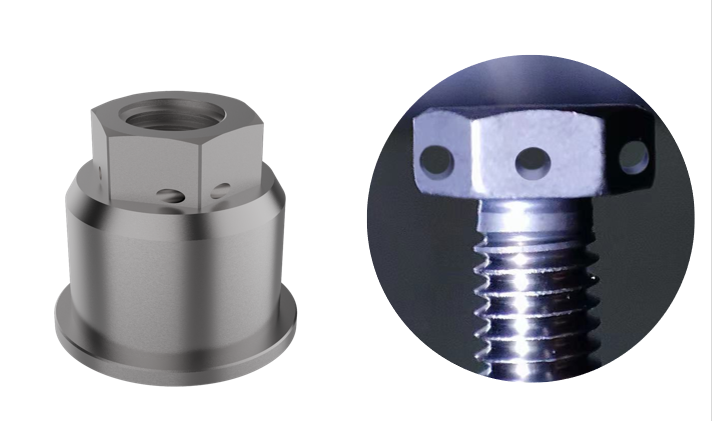

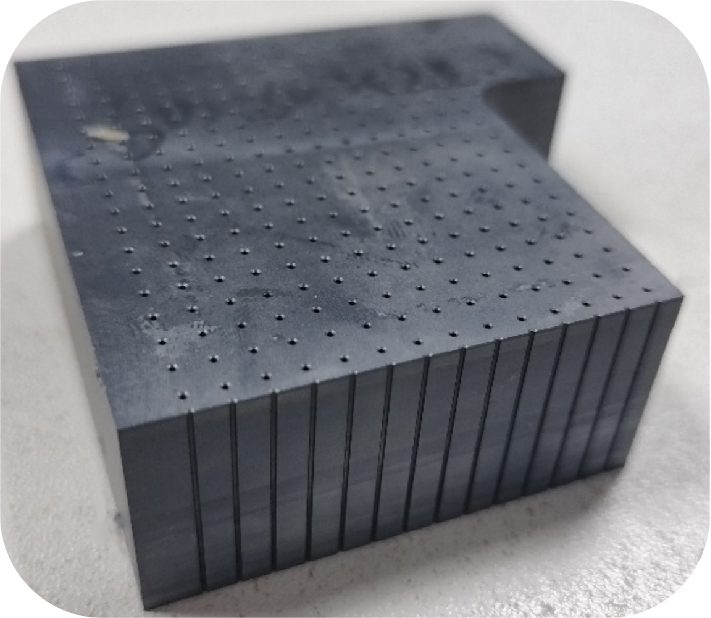

Workpiece

🔔 GH4169 Superalloy

🔔 HV560

Challenges

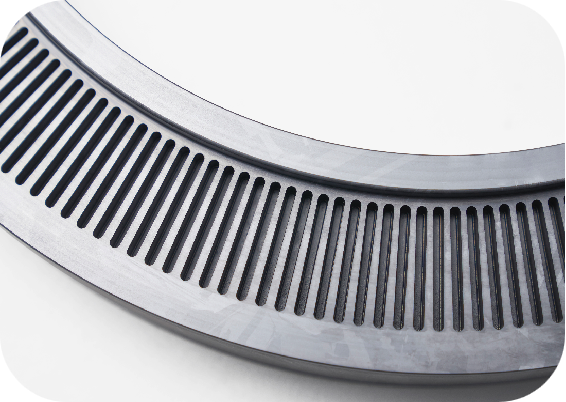

❌ Low machining efficiency with bench drill

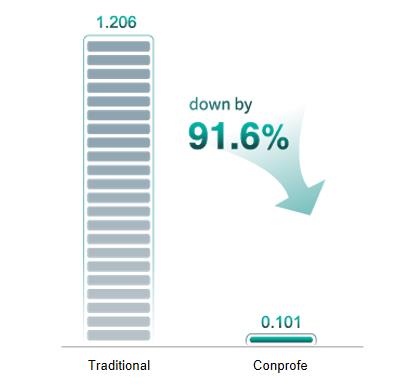

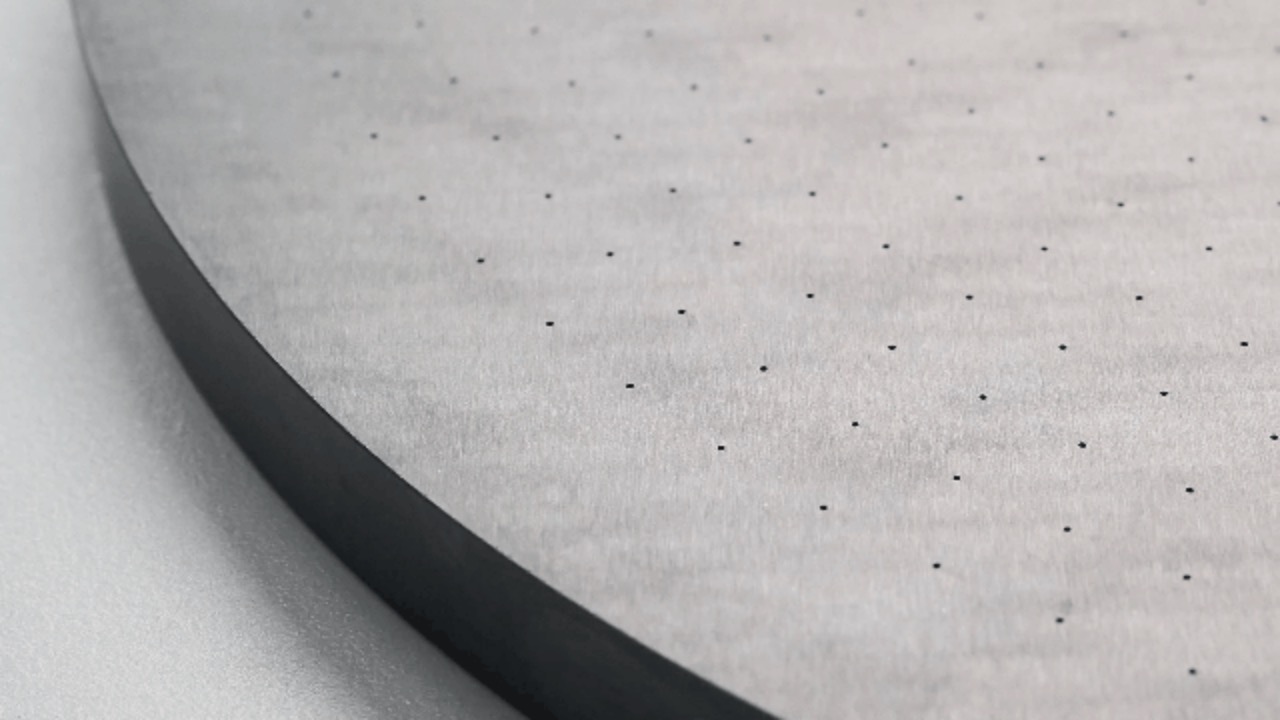

❌ Severe burrs with size up to 1.206mm

❌ Manual deburring necessary

Conprofe Benefits

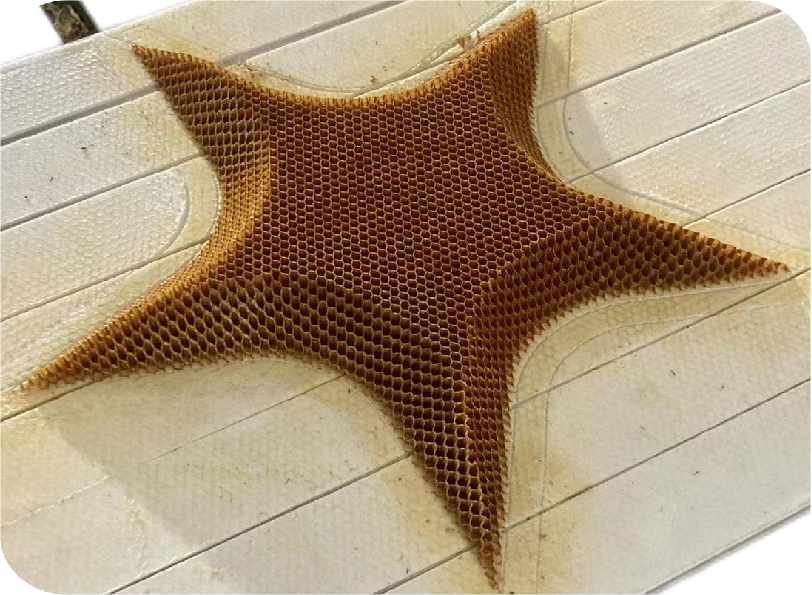

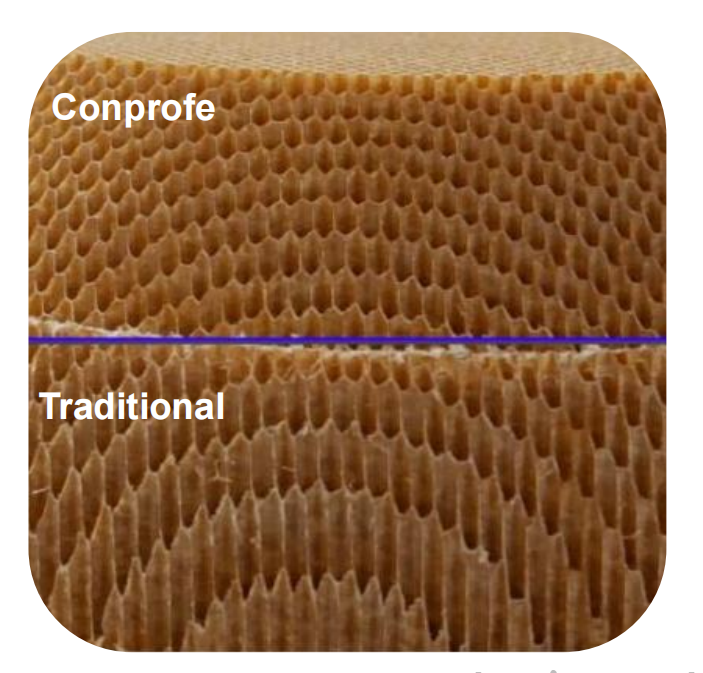

✅ Hole wall quality improved

✅ Burrs reduced by 91.6%, from 1.206mm to 0.101mm

✅ Cost saving from replacing manual operation with CNC machining

Burrs Size (mm)