Take the World by Storm

Recently, another 150 sets of Conprofe UHB-400 Ultrasonic Precision Engraving & Milling Center (hereinafter referred to as UHB-400) were shipped to customers at home and abroad.

Featuring compact design, excellent cutting performance and advanced ultrasonic machining technology, the all-in-one UHB-400 machine tools are widely recognized by customers in various industries at home and abroad.

Ultrasonic Precision Engraving & Milling Center UHB-400

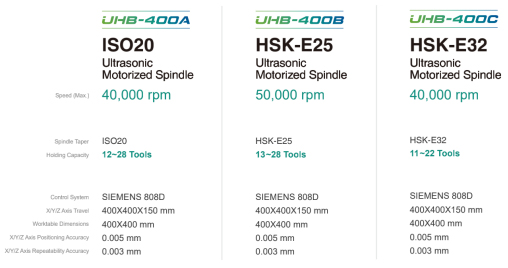

Main Technical Data

As advanced hard-to-cut materials become increasingly popular in industries such as consumer electronics, semiconductor, automotive, aerospace, medical and general precision manufacturing, many manufacturers are facing difficulties in shortening cycle time, extending tool life, and improving surface quality and machining accuracy in machining hard-brittle materials, hard-to-machine metals, composite materials, etc. At the same time, manufacturers are more prudent in equipment investment. How to achieve maximum output with minimum input to improve the cost competitiveness has become the most acute problem that they need to address.

Efficiency Times Up with Ultrasonic On

UHB-400 features ultrasonic machining technology, a cutting-edge technology that helps significantly boost machining efficiency.

UHB-400 comes with an ultrasonic machining system, which is independently developed by Conprofe. And the machining performance of the ultrasonic machining system, already gained more than 200 IPRs, has been tried and proved with a large number of application examples. With ultrasonic machining technology, UHB-400 enables better surface quality, longer tool life and higher machining efficiency in finishing.

The ultrasonic machining system mainly includes two key components: a Conprofe-developed ultrasonic spindle and a new generation of Intelligent Digital Ultrasonic Generator.

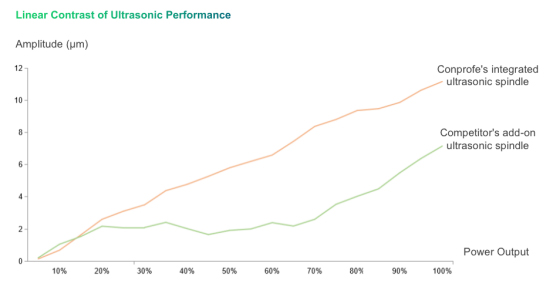

(1) The Conprofe-developed ultrasonic spindle is the first to realize the perfect integration of ultrasonic machining technology and spindle product. Compared with traditional ultrasonic application, Conprofe’s ultrasonic spindles deliver more stable and reliable machining performance thanks to higher cutting consistency and better structural rigidity. Conprofe ultrasonic spindles, with a max speed of 50,000rpm, come in a full range of specifications for various machining demands.

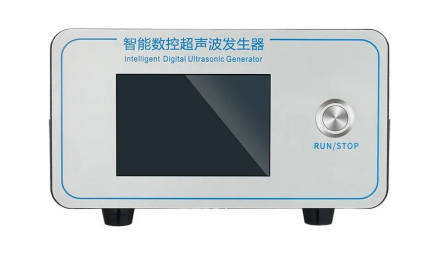

(2) New Generation of Intelligent Digital Ultrasonic Generator

New Generation of Intelligent Digital Ultrasonic Generator

Conprofe’s new generation of Intelligent Digital Ultrasonic Generator, adopting new functional feedback technology and impedance automatic matching technology, can automatically scan, match and track the frequency to achieve automatic power tracking and constant amplitude control of the transducer, and can realize adjustable output of linear amplitude to stabilize machining performance.

Compact Structure with Full Features

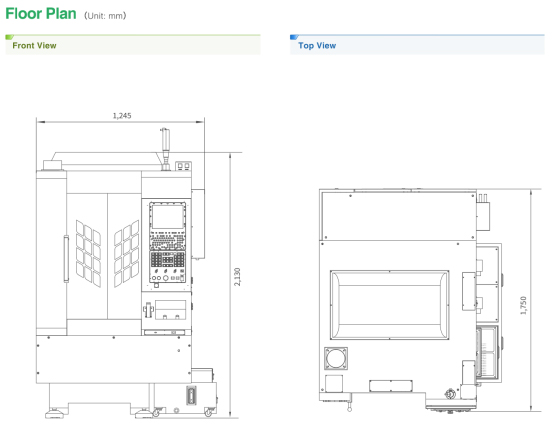

Compared with the machine tool of its kind, UHB-400 has a compact structure with a water tank covering an area of 2.5m2. UHB-400, with a total weight of 2.1 tons, can be put on the second floor, effectively helping customers to reduce site costs.

UHB-400 Floor Plan (unit: mm)

UHB-400: compact, well-configured and expandable

1. Extended Tool Magazine available

UHB-400 series machine tools can be configured with Extended Tool Magazine, with a holding capacity of up to 28 tools, to meet various machining demands and intensive production. Ultrasonic machining and traditional high-speed machining can be achieved in one single machine tool with only one click.

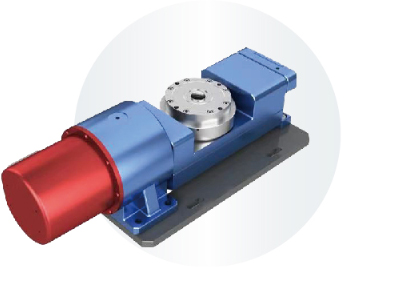

2. Optional 4-axis rotary table

UHB-400 can work with 4-axis rotary tables to realize multi-faceted machining in one single clamping, reducing unnecessary equipment investment.

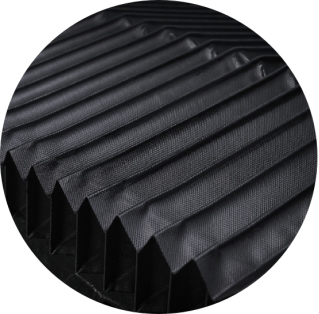

3. Unique double-layer protective shield

A double retractable protective shield is adopted in Y-axis in UHB-400 to better protect the leadscrew and guideway by preventing coolant, ceramic power and glass particles from entering the leadscrew and guideway in cutting hard-brittle materials.

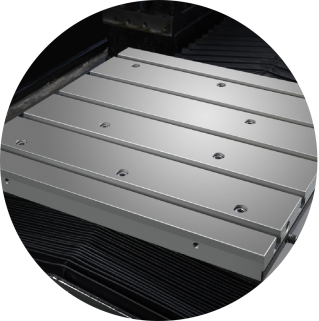

4. Double-layer worktable

UHB-400 adopts double-layer worktable. The upper layer made of aluminum alloy provides excellent anti-rust performance; and the lower layer made of cast iron ensures the rigidity of the worktable.

Cost-effective All-in-One

UHB-400 is ideally suitable for machining hard–brittle materials, metal parts, composite materials and producing high-gloss/mirror finish, delivering stable cutting performance with low machine and equipment investment.

Following are some of application examples of UHB-400 in machining hard-brittle materials, metals and composite materials and in producing high-gloss/mirror finish.

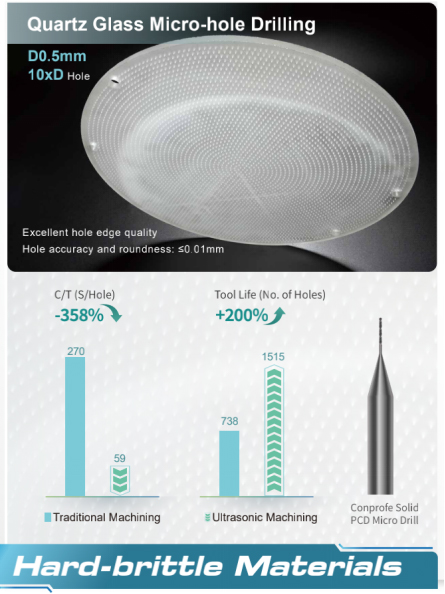

(1) Hard-Brittle Materials·Quartz Glass Micro-hole Drilling

Solid PCD Micro-edge Tool works with ultrasonic machining for excellent performance

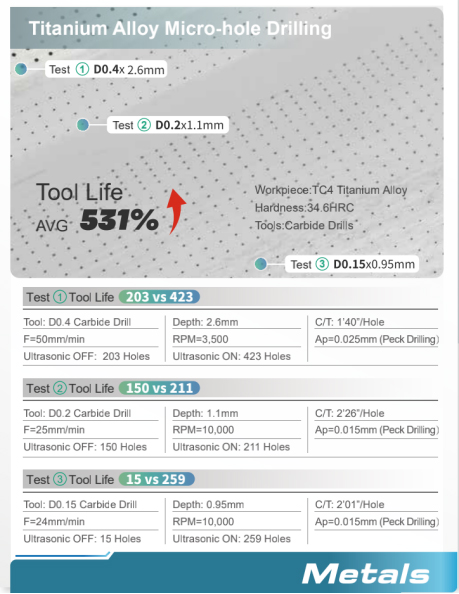

(2) Metal Parts·Titanium Alloy Micro-hole Drilling

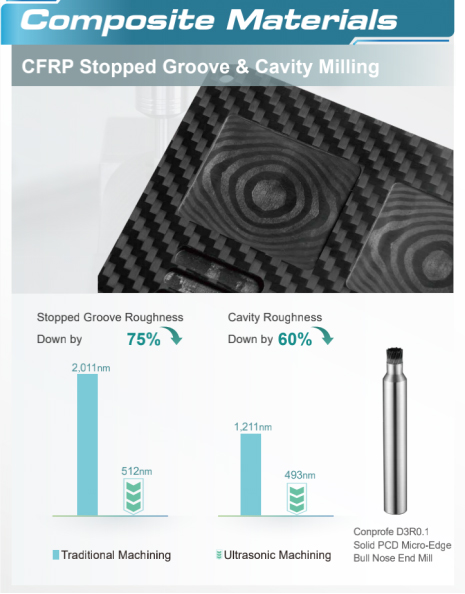

(3) Composite Materials·CFRP Stopped Groove & Cavity Milling

(4) High-gloss/Mirror Finish Machining

One-stop Solution with Excellent Service

With a complete product system from parts, units to complete machine, Conprofe stays committed to providing the best green and efficient intelligent manufacturing solutions for customers in various industries. Meanwhile, our professional service team and strong after-sales steam stay focused on ensuring best service for our customers. On the one hand, we will send engineers as needed to the production site to provide timely support to ensure smooth application and to help customers shorten product development cycle. On the other hand, headquartered at Guangzhou Science City, Conprofe has established sales and service centers in seven domestic regions and a network of R&D, sales and service based in Hong Kong, Taiwan, the United States, South Korea, India and Vietnam, etc., enabling us to respond quickly to customer demands, both in pre-sales and after-sales services.