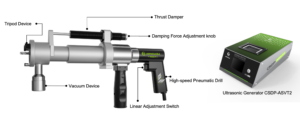

Innovative Dental Application | Breakthrough in Polishing-Free Titanium Alloy Abutment with Surface Roughness of 0.053um

The dental implant abutment, a holder of threaded structure implanted in artificial alveolar to connect the artificial dental crown, does play a crucial role in dental implant surgery. Titanium alloy, commonly used as an abutment material, boasts good bio-compatibility and connects nicely with human tissue, thus reducing the risk of rejection against the human body. Moreover, it has excellent corrosion resistance and rigidity,