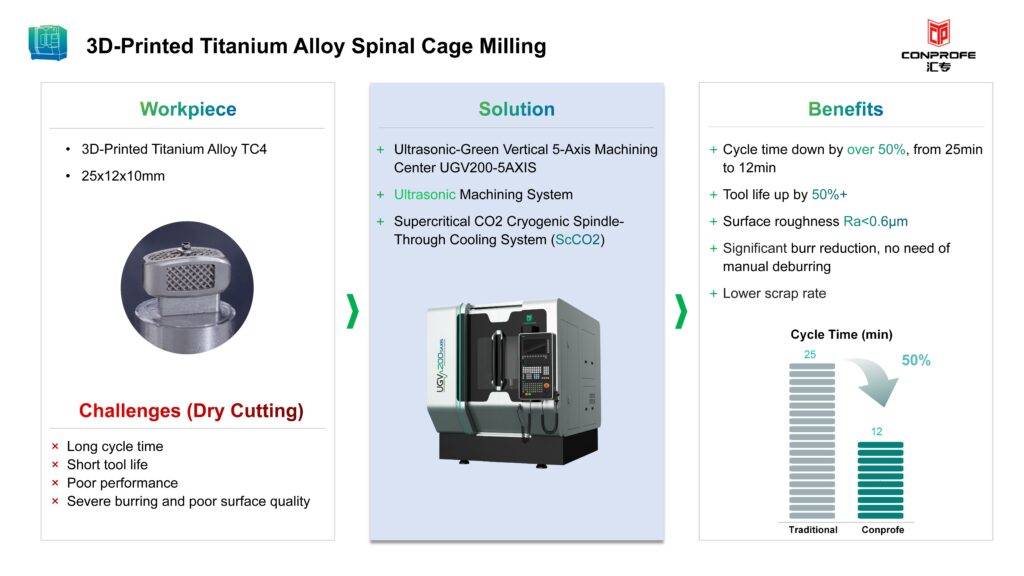

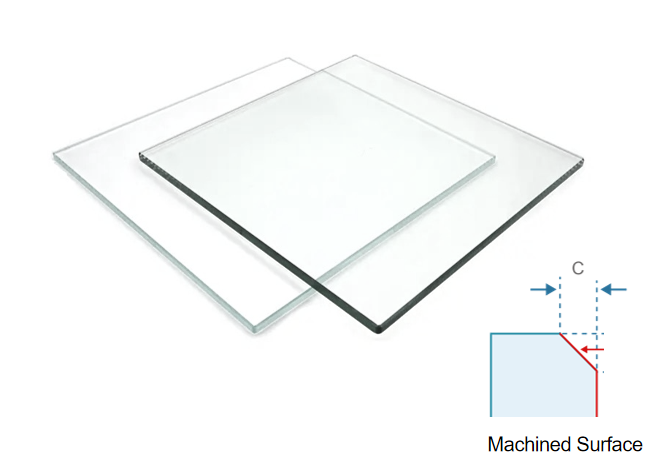

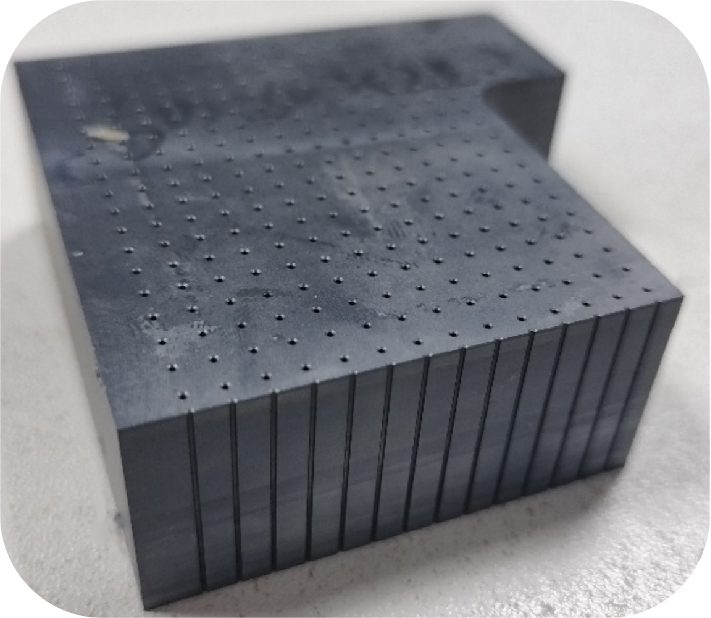

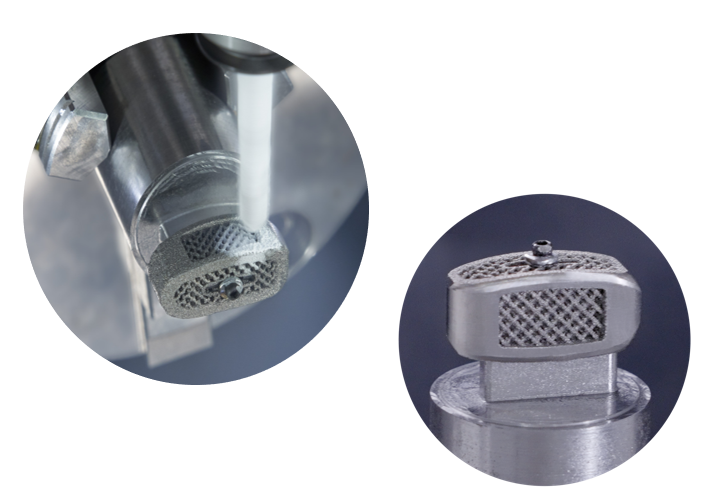

Workpiece

- 3D-Printed Titanium Alloy TC4

- 25x12x10mm

Challenges

- Long cycle time

- Short tool life

- Poor performance

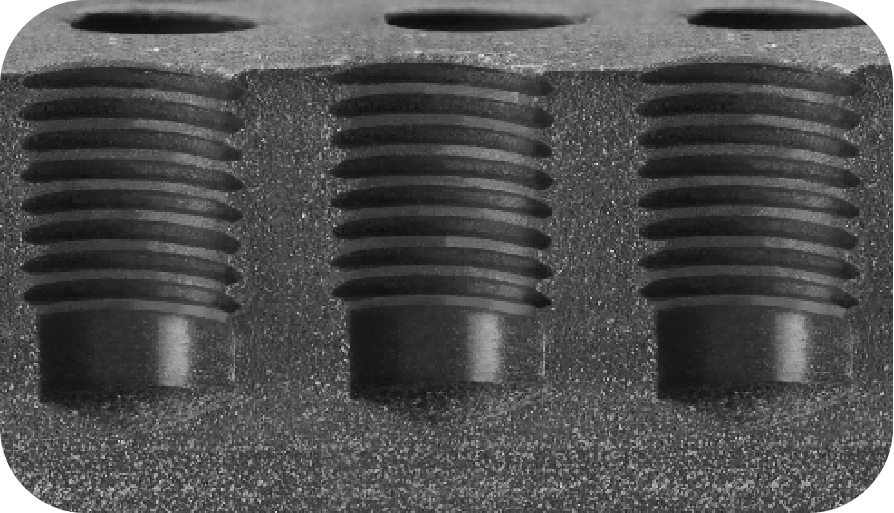

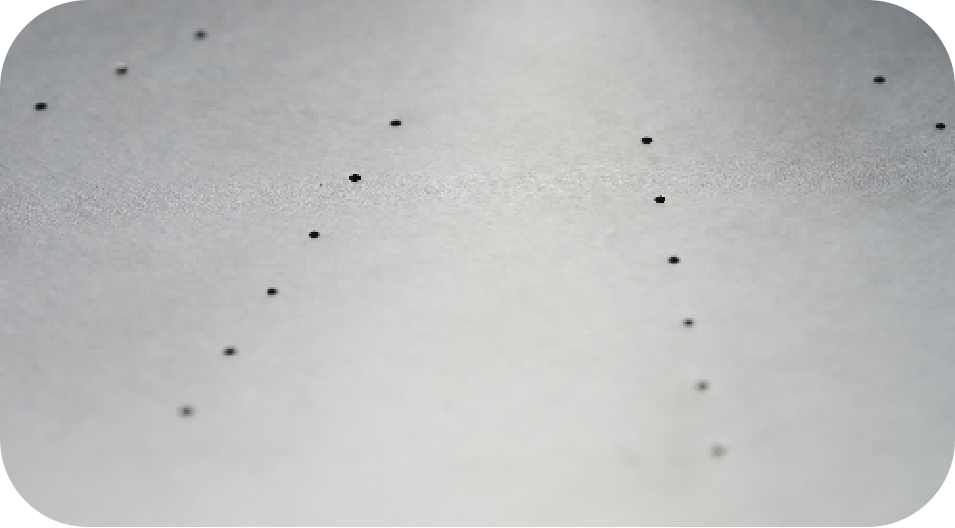

- Severe burring and poor surface quality

Benefits

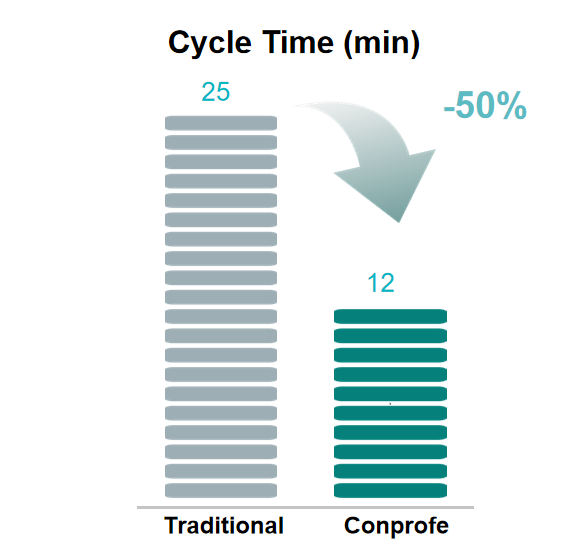

- Cycle time down by over 50%, from 25min to 12min

- Tool life up by 50%+

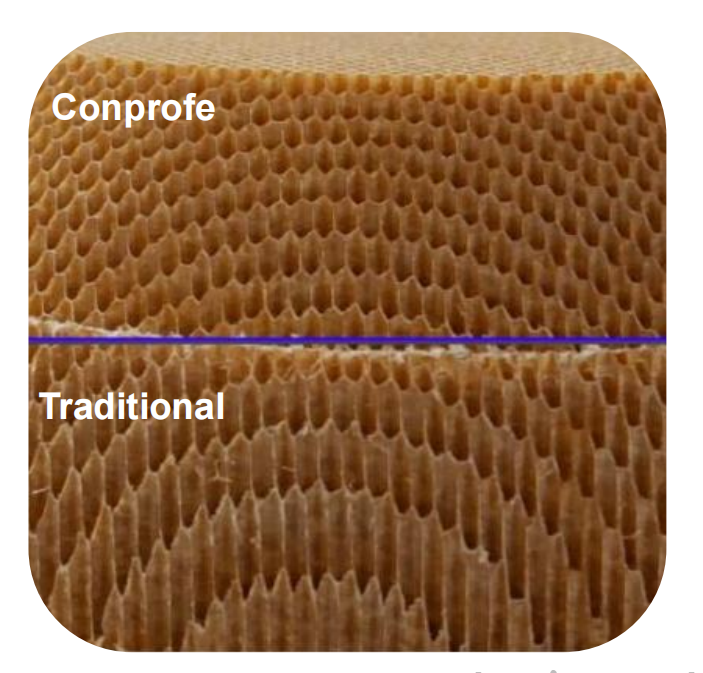

- Surface roughness Ra<0.6μm

- Significant burr reduction, no need of manual deburring

- Lower scrap rate